ELECTRONIC DIVISION INFRASTRUCTURE

Defsys has modern state of the art factories to carry out BTP manufacturing of complicated electronic systems for international defence OEM's as well as for Indian clients.

We have the following manufactiring capabilities and equipment’s:

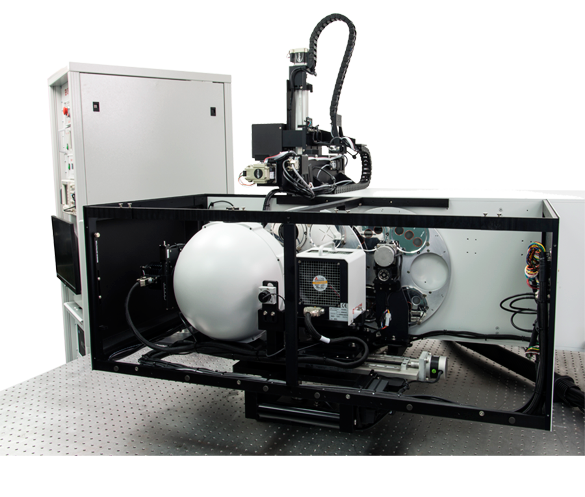

- Electro-Mechanical assembly halls

- Clean Rooms for optical assemblies and microwave sub-systems

- Electronic boxes integration and testing lab

- Large System Integration Facilities

- Compressed air and Compressed nitrogen systems

- Vibration Machines, Thermal Chambers and remote conditioners

- Collimators and Special optical test equipment

- RF Test and measurement equipment's up to 40 GHz